THE NEW PARADIGM IN AMMUNITION MANUFACTURING

FRAME tech (or simply FRAME) by applying cutting-edge technology and a rational concept, has not invented plate-based loading but it has made it easy, reliable, flexible, and, above all, has reduced the number of operators previously required by this technology.

FRAME is capable of operating in any sub-process of ammunition manufacturing (priming, assembly, inspection, packaging, reprocessing, etc.) and can handle cartridges ranging from .380 Auto to .338 LM and even .50 BMG.

THE CONCEPT

FRAME is a step-by-step manufacturing platform inspired by fractal geometry. Its configuration is based on a repetitive, self-similar pattern that, by applying very simple principles and rules, can give rise to highly complex solutions.

The workflow is fully automatic, although it can incorporate manual or assisted operations, providing the best solution for each specific need. Its operation can be integrated at any stage of the ammunition manufacturing chain.

OUTSTANDING OUTPUT

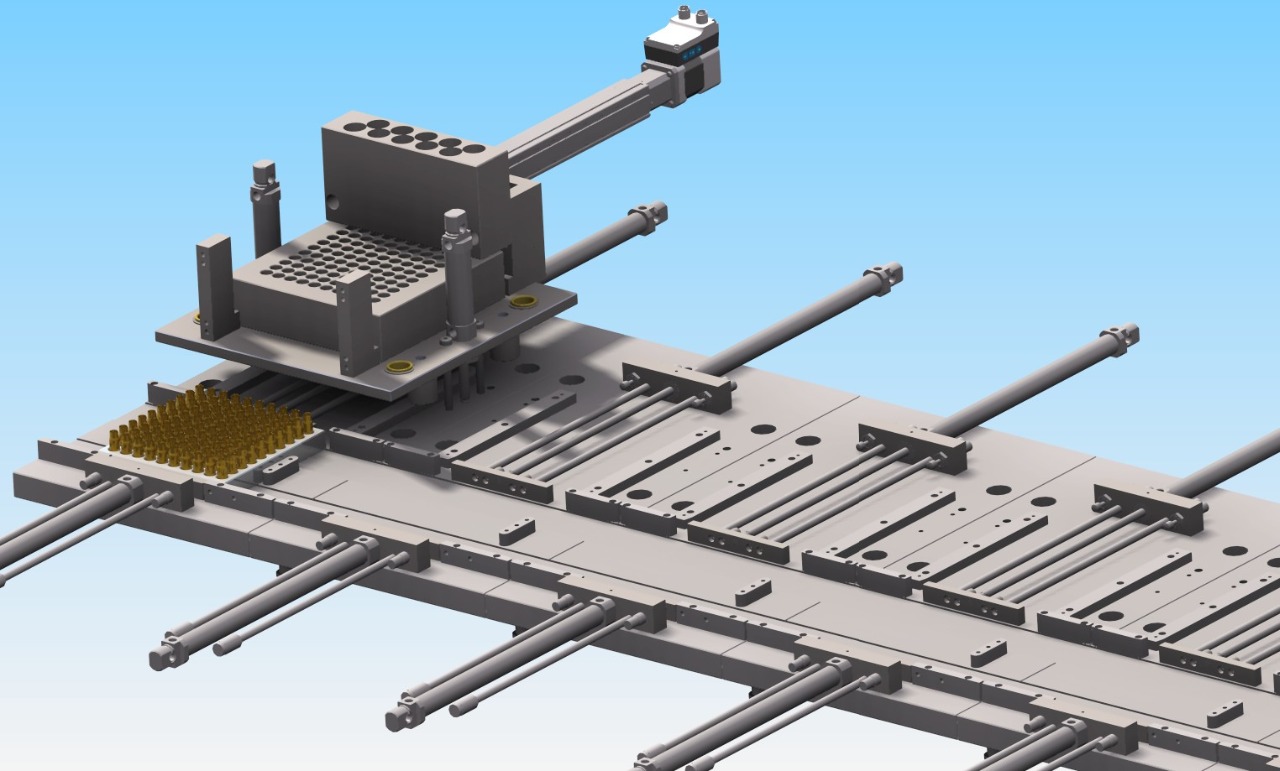

Through the plate-loading concept, the ammunition is managed on a plate containing up to 100 cartridges processed simultaneously. The minimum process time is 4 seconds per plate, which means it can achieve an output of up to 1500 cartridges/minute.

| Caliber | N | CPM |

| 9mm | 100 | 700 - 1500 |

| 5.56 x 45 | 100 | 520 - 1330 |

| 7.62 x 51 | 100 | 490 - 1080 |

| 300 WM | 64 | 275 - 530 |

| 338 LM | 64 | 270 - 480 |

| 12.7 x 99 (*) | 36 | 120 - 145 |

(*) Requires special setup.

QUALITY CONTROL

The work units dedicated to quality control, using a variety of technologies, allow virtually any characteristic or aspect of a cartridge to be controlled, eliminating the need for costly and unnecessary external inspection processes.

Quality control can be performed using our high-speed optical control system (patent pending), which scans the moving plate to check for the specific feature for which it has been configured.

When these checks are insufficient, a work unit equipped with 3D scanning technology can be added to verify the key dimensions of each cartridge individually. Additionally, vision and image recognition cameras, using different lenses and lighting, can detect stains, scratches, and other surface defects.

AMMUNITION PROCESSING STATIONS

The work is organized in a chain of processing stations. Those stations consist of a base and a work unit. The combination of these two elements acts as a single unit capable of carrying out a defined process operation. The base, attached to the structure of the machine, supports the work unit and manages the movement of the plates. Once the plate is in the correct position, the work unit performs the processing operation for which it has been designed.

The work units can handle the different components (primer, bullet, case, or powder) to carry out various actions with them (feeding, inserting, crimping, resizing, etc.), as well as monitor the progress of operations using different inspection technologies (optical, laser, 3D scanning, or machine vision). In addition, they can also manipulate an entire plate to enter or leave the workflow, unload material, or simply flip it over to work on the other side.

FEEDING AND DISCHARGE

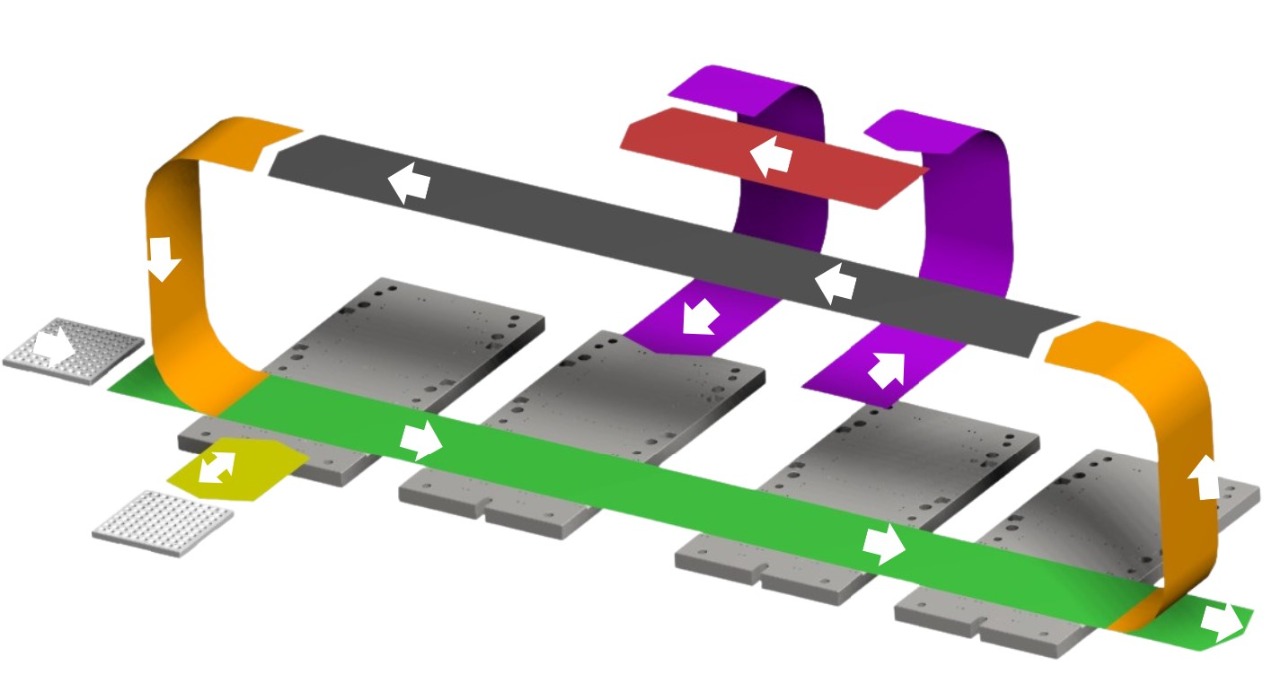

FRAME automatically manages the plates containing the ammunition, moving them from one station to another, adding and removing plates as needed, and loading and unloading components, without restricting the process and optimizing the required human resources.

COMPACT DESIGN WITHOUT LIMITS

The machine is the structure that houses the stations, provides power, enables the transport of plates between stations, and includes safety and control systems. Stations are assembled in-line, and a single machine can accommodate 4, 8, or 12 stations. It also allows for inactive stations (without a work module) or simply empty stations to fill available space.

Machines can be linked in series to create a process with as many stations as required, with no preset limit. This also allows a process to be expanded at any time as needed while preserving the investment, since stations and work units are fully interchangeable.

EXAMPLE: 2x 12 stations machines linked.

MORE INFORMATION:

- Download brochure: FRAME Technology overview.

- Contact us

-

Visit us at IWA Outdoor Classics ( booth #1-342) from 26 February to 1 March 2026 too see a live demo

Click here to arrange a personal meeting.